無断複製・転載禁止

このたびの令和6年能登半島地震で被災された皆さまに、心よりお見舞い申し上げます。

-

カーテン・カーペット・ラグ・業務用床材CURTAIN/CURPET/RUG/FLOORING SOLUTIONS

カーテン・カーペット・ラグについて キーワードや条件で商品検索していただけます。

-

業務用床材サイト (外部サイト)FLOORING SOLUTIONS

業務用床材のすべてが詳しくご覧いただけるページです。タイルカーペットは色・柄のシミュレーションができます。

-

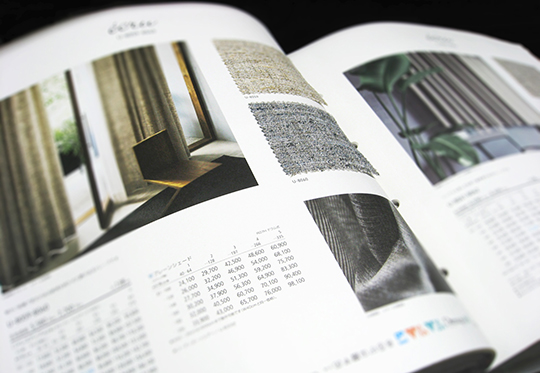

見本帳一覧SAMPLE BOOK LIST

デジタルブックがご覧いただけるほか、

画像やPDFのダウンロードページです。 -

オンライン展示会動画一覧ONLINE EXIHIBITION MOVIE LIST

過去のオンライン展示会の動画をご覧いただけるページです。

ショールームSHOWROOM

エンドユーザーの皆さま、ならびに販売店・設計・コーディネートご担当のプロフェッショナルまで、インテリアに関するお問い合わせとご相談は、「スミノエ ショールーム」がサポートいたします。

スペースのイメージを広げる豊富な商品アイテムの展示とトータルインテリアシステム。

最新のインテリア情報をもとに、バラエティあふれるライフスタイルを実現。きめ細やかなサービスとネットワークがモットーです。

お近くのスミノエ ショールームへ、どうぞお気軽にお立ち寄りください。

OSAKAショールーム大阪

TOKYOショールーム東京

-

- お知らせ

-

TBSテレビ金曜ドラマ『9ボーダー』の撮影シーンに、SUMINOEの「水平循環型リサイクルタイルカーペット『ECOS®(エコス)』」と「ロールカーペット」が採用されました

TBSでは、4月期の金曜ドラマ枠(毎週金曜よる10時)で、『9ボーダー』(読み:ナインボーダー)の放送が4月19日(金)よりスタートいたしました。 その撮影シーンに、SUMINOE GROUPの「水平循環型リサイクルタ […]

-

- お知らせ

-

SUMINOE SHOWROOM ゴールデンウイーク休業期間のお知らせ

平素は格別のご高配を賜り、厚く御礼申し上げます。 SUMINOE SHOWROOMのゴールデンウイーク休業期間は以下の通りです。 誠に勝手ではございますが、宜しくお取り計らいくださいますようお願い申し上げます。 記 […]

-

- お知らせ

-

日本テレビ系“土ドラ9” 『花咲舞が黙ってない』【毎週土曜よる9時放送】の撮影シーンに、SUMINOEのビニル床材「スミリウム」が採用されました

日本テレビ系“土ドラ9” 『花咲舞が黙ってない』【毎週土曜よる9時放送】の放送が4月13日(土)にスタートいたしました。 その撮影シーンに、SUMINOE GROUPのビニル床材「スミリウム Stone CT ライムス […]